Automatic Double Computerized System Flat Knitting Machine

DESCRIPTION OF PRODUCT

Basic stitches like plain stitch, rib fabric, links and links,

interlock stitch, etc. can be knit on a flat knitting machine.

Jacquards with uneven patterns, weft arrangements with twit

flowers, cordweave, racking stitch, cable, etc.

Knitting sweaters, collars, uppers for shoes, and school uniforms

can be done on a flat knitting machine using materials including

synthetic, wool, acrylic, mixed fiber, and yarn.

ready-made clothing items like hats, scarves, and cardigans.

PRODUCT FEATURES

| MODEL | GSJX-1-52 |

| GAUGE | 10G,11G,12G |

| KNITTING SYSTEM | SINGLE SYSTEM SINGLE CARRIAGE |

| KNITTING WIDTH | 52INCH |

| KNITTING SPEED | 1.2m/s MAX.1.2M/SEC |

| KNITTING FUNCTION | TRANFER,TUCK,MISS,JACQUARD,INTARSIA,HIDE OR APPARENT SHAPING. |

| STITCH DENSITY | STITCH SYSTEM CONTROLLED BY STEPPING MOTOR,32 SECTION STITCH

SELECTABLE,ADJUSTABLE

SCOPE SUPPORTED BY SUBDIVISION TECHNOLOGY:0-650 |

| RACKING | CONTROLLED BY AC SERVO MOTOR,RACKING WITHIN 2 INCHES AND WITH FINE

ADJUSTIING FUNCTION. |

| DRIVE SYSTEM | SYNCHRONOUS BELT DRIVE,AC SERVO SYSTEM |

| NEEDLE SELECTION | CONTROLLED BY COMPUTER,ELECTRIC MAGNET NEEDLE CHOOSE SYSTEM WITH

HIGH EFFICIENCY. |

| YARN CARRIER | 1x8YARN CARRIERS ON EACH SIDE OF 4 GUIDE RAILS,SHIFTABLE ON ANY

NEEDLE POSITION |

| TAKE DOWN ROLLER | PROGRAMMED INSTRUCTION CONTROLLED BY STEPPING MOTOR,32 SECTION

LEVELS SELECTION

ADJUSTABLE AREA:0-100 |

| PROTECTION SYSTEM | THE MACHINE WILL AUTOMATICALLY ALARM IF YARN BREAKING,FLOAT

YARN,REWIND,END OF KNITTING,

FAIL OF RACKING,NEEDLE BREAKAGE AND ERROR PROGRAMMING OCCUR ECT. |

| CONTROL SYSTEM | 1,ADOPT LCD SCREEN,INPUT DEVICE:USB,SYSTEM MEMORY 256MB,A GREAT

AMOUNT OF

DESIGN FILES CAN BE STORED.2,MONITORING MENU,EACH KIND OF OPERATING

PARAMETER,

CAN BE SHOWN,AND THEY CAN BE ADJUSTED AT ANY TIME WHEN THE MACHINE

IS RUNNING.3,DESIGN

SYSTEM IS VISUAL AND EASY TO UNDERSTAND AND UPGRAD.4,MULTI LANGUAGE

VERSION,THERE ARE

CHINESE,ENGLISH ETC. |

| POWER | 220V ,SINGLE-PHASE,HAVE MEMORIZING FUNCTION AT THE POWER-OFF MOMENT |

PRODUCT DETAILS

LCD DISPLAYER

Machine uses an industry-standard LCD display with touch

functionality and continuous monitoring.

The information on knitting quantity, time, speed, roller, density,

yarn carrier, etc. is clearly shown and can be altered as needed.

It is the most practical and effective technique to change the

data.

PERPETUAL KNITTING

Continuous knitting can be done on the machine.

Circular weaving may produce a variety of patterns. Only all the

pattern files that will be executed must be saved in a consistent

manner when many separate pattern files need to be woven.

The machine will automatically choose the remaining patterns for

weaving when the first one is finished, saving time and yarn while

also making

SINKER SYSTEM

Flat knitting machine for knitting needle movement in the rise and

fall with the regularity of the moment,to achieve the stitch

transfer,stitch press off,stitch knit,stitch tuck such as knitting

effects,need to help latch needle from sinker to complete,improve

the capacity of weaving.Sinker control system make the function of

sinker adjustable to achieve.

TRANSPORTATION DEVICE USING YARN

The yarn transportation device is placed between the knitting

system and the yarn bucket,

considerably reducing the uneven stress brought on by the lengthy

yarn travel.

The sensor in the yarn transportation device will alarm and the

machine will cease operating if the yarn is used up or breaks for

any reason.

This stops broken yarn from getting into the knitting area,

facilitates easy yarn connections, and prevents harm to the

fabric's quality.

Protection from power failure

With power failure prevention, the machine may continue working in

accordance with the programmed patterns during a power outage by

automatically memorizing the data and retrieving it when the power

is restored. This prevents yarn waste and saves time without

sacrificing the fabric's quality.

BRACKET FOR SIDE YARN

High performance springs are used in the side yarn bracket to apply

direct force to the yarn-picking portion.

In addition to transferring yarn with a certain tension to the

knitting ear, it also has the ability to pick up extra yarn when

the carriage stops moving when changing directions, tensing the

yarn under a specific tension, and ensuring that the knitting is

normalized.

The side yarn bracket contains safety alerts, sensors that are

impervious to environmental interference, and is able to maintain

its sensitivity throughout.

APPLICATION FIELDS

WHAT WE DO

A reputable producer of computerized flat knitting machines, shoe

upper knitting machines, winding machines, linking machines, and

bracket machines, Changshu Guosheng Knitting Machinery Factory was

founded in 1992 and is situated in Changshu city, close to

Shanghai.

"YIMA" and "GANGJI" are the two leading brands. With approximately

400 employees, the firm has a 30, 000 square meter footprint and

produces 10,000 sets a year.

We want to lead the pack among producers of textile equipment for

innovation and price. Our knowledgeable staff members are always

accessible to discuss your needs and guarantee complete customer

satisfaction. They are committed to tight quality control and

considerate customer care. Our business has just unveiled a variety

of cutting-edge machinery.

POWERFUL TEAM OF AFTER-SALE SERVICES

As soon as you purchase our machine, you will receive free machine

operating instruction and pattern-designing training.

Guosheng's guiding concept for customer care is mature, attentive

service. To allay clients' concerns, Guosheng offers free machine

operating instruction as well as free pattern design training.

Best Price for a Double Carriage 80-inch Auto Flat Bed Knitting

Machine

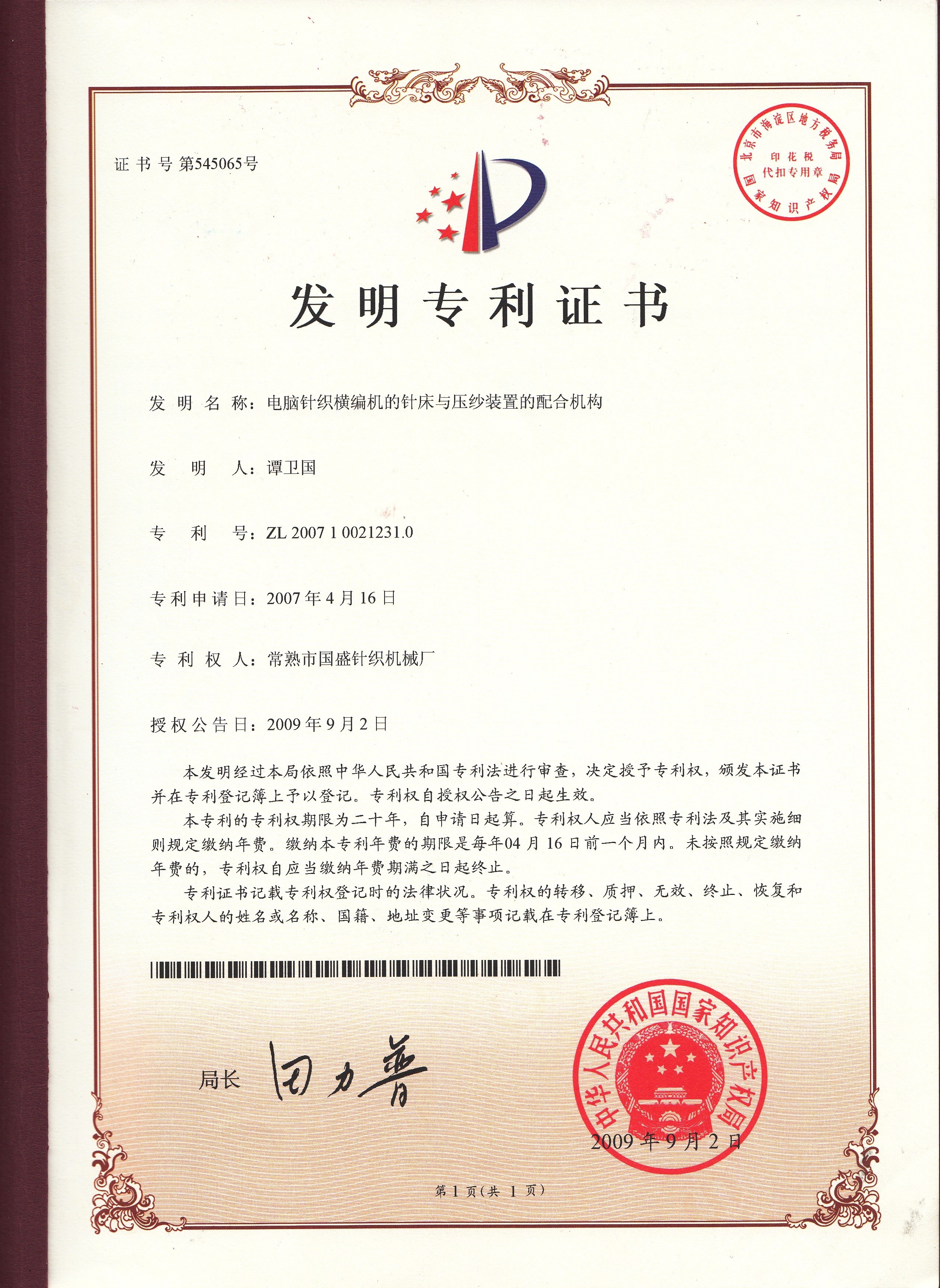

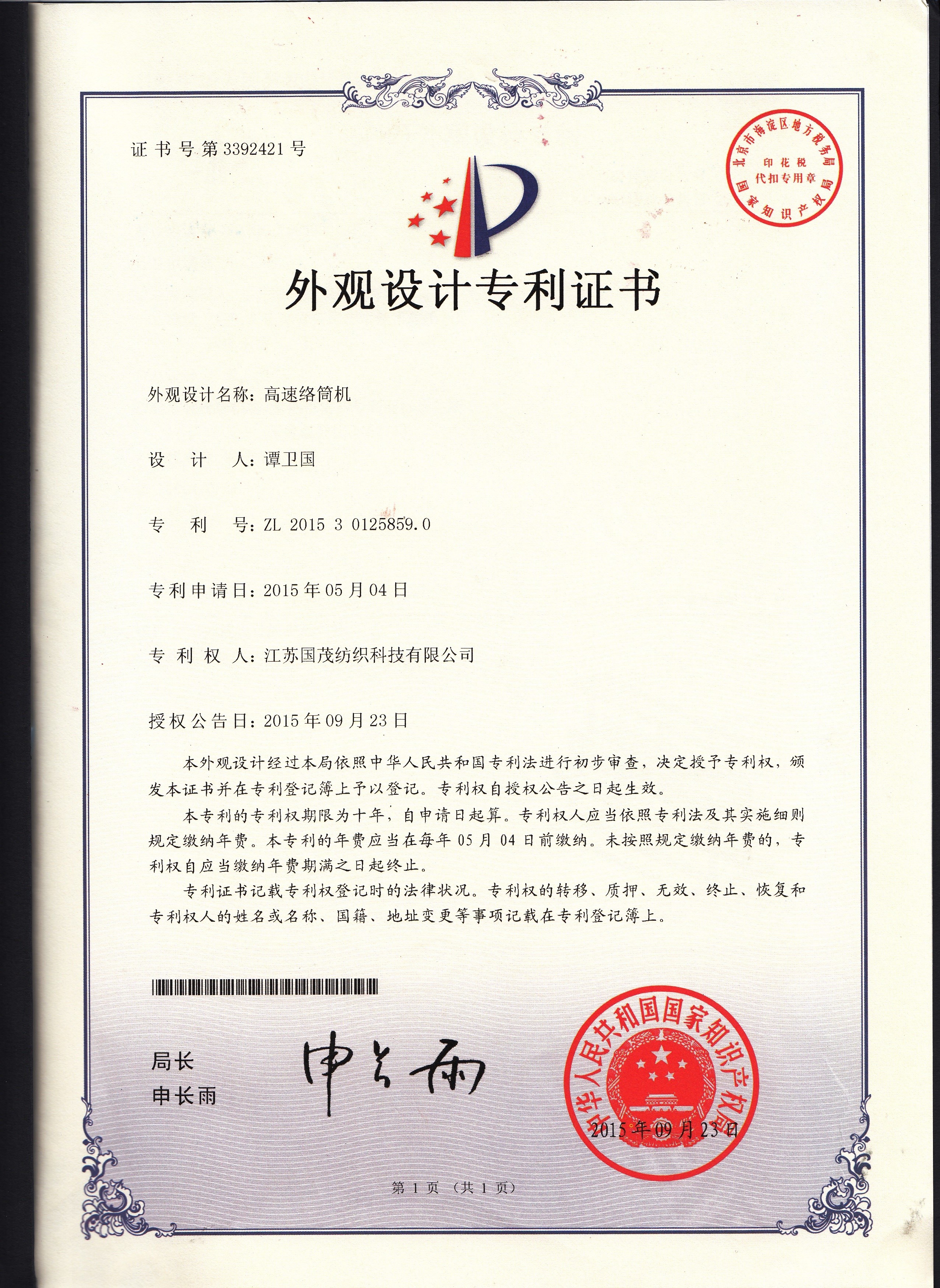

CERTIFICATIONS